Introduction

Today food is all about communication. Consumers want to know what they eat: is it healthy, safe, fresh and locally produced? This use case increases product quality and safety in the pork value chain by providing a transparency system to support pro-active auditing. Pro-active auditing stands for an inspection process that enables the auditor to continuously check whether farmers meet certification criteria and provide them with timely assistance in case non-conformity arises. The concept of proactive auditing is being developed together with the Sustainable Pork Association in the Netherlands that has strict sustainability criteria such as minimum weaning age, regular veterinary inspections and the strive for antibiotics-free products.

Standards for transparency data

Lack of transparency in meat supply chains is a major problem, which has become evident from recurring crises and scandals involving meat products.

Show more

A chain-wide transparency system enables food operators to manage data internally within their facilities and to share information with external food operators and stakeholders. Internal transparency enables for instance slaughterhouses to track and trace pig and meat products from slaughter until a meat product leaves the facility. But, if the slaughterhouse wants also to provide the welfare state of the animal from which the meat product came, it needs data from the farm. To have true transparency about meat products, a transparency system that goes beyond the individual company and that incorporates the sharing of data among key supply chain actors, referred to as external transparency, is essential. When suitable internal and external transparency systems are not in place the desired true transparency about the meat product cannot be realised.

Internal transparency requires capturing the events that take place within the food operators. In the meat sector these events concern the things that happen to animals at farm, such as birth, feeding, treatment and movement, and the things that happen to animals and meat product at the slaughterhouse and subsequent meat processing facilities, such as slaughtering, cutting as well as meat processing and storage. To realise external transparency feed companies, farmers, slaughterhouses, meat processing and retailers should use an internal transparency system and in addition these systems should comply with common standards for sharing transparency data.

A common solution for addressing such challenges is the use of a reference architecture. A reference architecture means a model of generic information system that will apply for all food operators across a particular supply chain or even for entire sector. However, deriving a concrete architecture for each of the food operators (such as for farmers and slaughterhouses) involves many different design decisions as a farming processes are very different from the processing in the slaughterhouse. Moreover, once a concrete architecture has been derived implementing the system based on the architecture is far from trivial. Therefore, often, third-party service providers, such as EECC in Germany, facilitate chain-wide transparency by providing and managing transparency systems. In order to develop the designs for workable transparency systems, the third parties work with food operators, researchers and transparency standardization bodies in order to derive models that constitute the desired reference and concrete architectures.

real-time

Feedback on farming practices

To improve transparency and traceability in the pig supply chain, Ayalew Kassahun, the Use Case Coordinator, and his team developed an ICT solution to collect, store and share meat-related quality data and traceability data from farmers, a feed company, a slaughterhouse, experts in the pork sector, and farm management software providers. The solution includes information on quality aspects of feed, farm and meat processing gives access to those data to auditors and other actors that ensure product quality. Unsurprisingly, data access as well as integration are the major challenges for this use case. Therefore, the team builds on top of the EPCIS standard to further develop the IoT and meat quality dimensions. The EPCIS standard and other related standards for identifying products, businesses and locations in a unique and unform manner across the globe are developed by GS1, a global not-for-profit organisation that has member organisations almost in every country and has over 2 million businesses members. By employing widely adopted standards such as EPCIS, sensor and other data, including logistics, retailers and eventually consumers data, which is necessary for transparency across the supply chain can be integrated. EPCIS standardizes data the describe that things that occur in the same manner. Thus, ultimately, all relevant data collected on the farm or at the slaughterhouse are transformed to EPCIS events and stored in an EPCIS repository.

Partners in the use case are Wageningen University, GS1 Germany GmbH, De Heus (feed company), Westfort (slaughterhouse) that together with the De Hoeve association formed KDV (Sustainable Pork Association). Together they support around 300 farmers who are part of the De Hoeve cooperative to communicate their practices to retailers and consumers. This includes information about animal friendliness and the use of certain medication. The data is collected at the farm by the farmer and through manual and automated process in the slaughterhouse with the help RFID tags. While improved transparency contributes to higher margins, it also allows the detection of problems across the chain, potentially leading to higher product quality and reduced overall waste. The use case infrastructure consists of several parts. Firstly, are the EPCIS repositories we described previously. On top of those repositories, several apps are developed to add functionality to the infrastructure. To transform farm events into EPCIS standard, the use case team developed a connector. The other events are captured directly from a farm management system or indirectly from an SIS (slaughterhouse information system). Key aspects of the architecture for the infrastructure thus are the use of the global standard for event information exchange (EPCIS) and the use of global identification standards such as GTIN, SGTIN and GLN.

Advantages for every stakeholder group

The new meat transparency system distinguishes two major groups that can use it: meat supply chain partners and auditors or regulators. Let us summarise the benefits for each of them in this chapter.

Show more

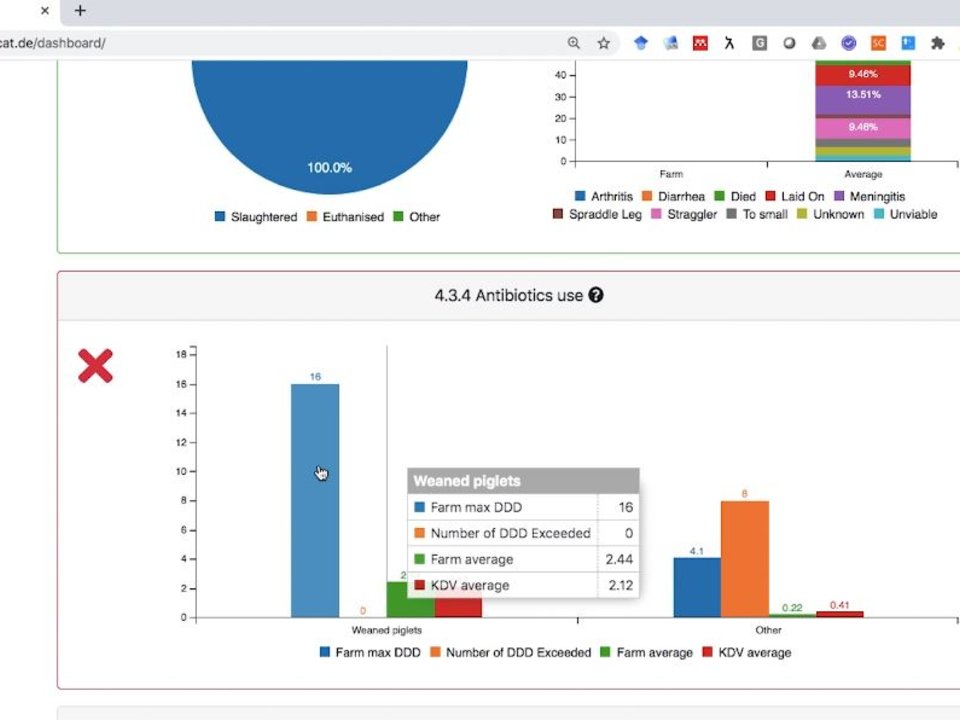

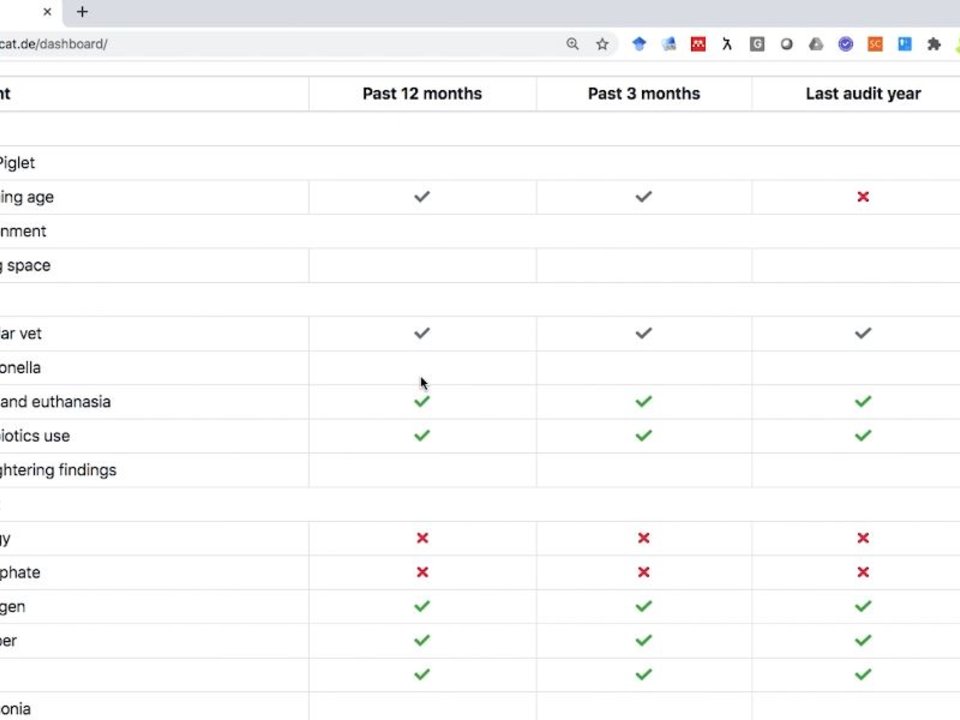

Supply chain partners benefit from the meat transparency system. Farmers, for instance, get real-time information about the state of their performance in relation to the quality certification scheme they adopt (compliance) as well as in comparison with their peers (benchmarking). This facilitates the differentiation of products from other farms or cooperatives. Moreover, a farmer’s investment in sustainability or in animal welfare becomes visible to their customers and eventually to the meat consumer. In this way farmers communicate with the consumers of their products. Farmers, slaughterhouses and meat processors can base products better on the requirements of consumers and other meat supply chain partners.

The proactive auditing system targets primarily auditors, who needs the systems the most. The motto has been: if it is good for auditors, then it is good for all stakeholders including the consumer and authorities. Until now auditing traditionally happens only once a year. By using the use case innovation, auditing can happen any time and in a proactive manner. Thus, focus is on providing feedbacks and avoiding mistakes, instead of sanctions after problems have already occurred. The same solution can be used by food authorities. They can monitor, control and enforce regulations more easily in case of a meat alerts such as the horse meat scandal. The new meat transparency system enables a fast, effective, surgical response by authorities with less critique by the media and the general public. In these regards, the society as a whole benefits from the transparency system as it rewards investing in ethical and environmentally friendly farming styles focused on sustainable production as well as animal welfare.

-30%

Inspection or audit time

By developing a dashboard that supports proactive auditing and enabling the stakeholders to market pork meat with trustworthy quality statements and labels, this use case has achieved to relate specific business objectives in the processing of meat to transparency and traceability on the product level. At the end of the use case the team learned from their stakeholders that proactive auditing has revolutionised their practices. The approach has now become crucial to their business model. The use case partners mentioned that they have already invested a substantial amount of resource in the RFID tag system and the associated software. Therefore, all the necessary means to develop their own dashboard are already in place. This was great news for the use case team since user acceptance is an important factor of widespread technology adoption. It has become clear within this use case that transparency is an underlying concept and not a business proposition alone. Value has to be created with transparency, proactive auditing for quality labels is just one such value proposition. If a proposed solution has a major business value, the stakeholders can align their market strategy and decide to choose to develop the tools and dashboards themselves. Since this use case represents such a setting and procedure, they could create synergies beyond the meat supply chain. In collaboration with the Digital Ecosystem Utilisation use case, the same transparency standards and platform have been applied for realizing transparency from field to retail table in the olive supply chain pilot conducted in Greece. The successful completion has allowed this pilot to be considered for inclusion in GS1’s case study library database where outstanding implementation of GS1 standards are advertised.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

Solution for sustainable pork supply chains certification schemes

Improved quality of transparency data

Enabling auditors to constantly detect non-conformances

Check critical KPIs like growth & mortality rate in near real-time

Implementing well-established GS1 standards like EPCIS