Introduction

Producing high-quality food with a low ecological footprint and high animal well-being is one of the greatest challenges of modern livestock production systems. In order to fulfil these requirements, farmers invest more into their properties, resulting in high-value farms and an increasing necessity to guard, track and monitor all assets with the help of innovations. Those technologies need to integrate seamlessly and proactively to turn the industry into a smart and sustainable one. While the number of connected devices continues to rise simultaneously with the growing demands on the agri-food sector, particularly precision livestock farming requires reliable, affordable, low-power, wide-range network technologies and smart sensors (LoRa and NB-IoT). As those IoT applications play an important role in this use case, leveraging their key characteristics is crucial. The system is thus made up of a small rumen bolus, monitoring (temperature, rumen and body activity, pH level), and a cloud-based application to provide accurate information for daily operations. At the same time, involving connected supply chain stakeholders across different regions helps to further develop and deploy the latest innovations required to perform efficient and sustainable livestock farming and animal breeding.

Remote cattle monitoring

In livestock farming, monitoring the physiological functions of cows is key for efficient operation and production. Deploying different monitoring devices means operating in an unstable network and having high costs for gateways, relays and cabling to achieve coverage.

Show more

Challenging tasks which increase in complexity with a growing farm size. Therefore, Peter Gesler, the Use Case Coordinator, and his team from Moonsyst developed a solution adaptable to any farm size. Whenever these values reach a critical level the farmer is alerted through a push notification, giving them the ability to adjust conditions accordingly. The temperature supports the illness detection while the rumen pH value gives the end-user insights regarding feeding control. Moreover, the smart rumen bolus can track the activity such as general movement and heat detection.

+55%

Successful insemination rate

+80%

Heat detection accuracy

-5%

Treatment costs

When we visited this use case in Hungary, we became witnesses of the solution’s adaptability. The first farm we were invited to belongs to Jozef, who welcomed us with open arms and delicious traditional Hungarian food at his family farm. The next day we saw another testing site which could not be more different in terms of setup and size. The hospitality, however, remained. Something else unites both test farms: they resemble a paradigm shift of agriculture. While Jozef uses the innovation to facilitate and optimise his daily work, the second testing site brings cutting-edge technology from all over Europe together to demonstrate the future of livestock farming. We are talking about automatic manure removal, waterbeds to improve the cows’ comfort, milking and feeding robots alongside IoT devices. One of those technologies is the solution of this use case which puts them at the forefront of an agricultural revolution. Since the requirements of those two testing sites differ significantly, the researchers had the chance to demonstrate the added value under conditions. After all, delivering the desired results is key in terms of end-user adoption. The challenges that dairy farmers face these days remain similar, regardless of farm size. They all wish to improve heat detection and insemination accuracy the farmers are concerned about the well-being of their animals and a solution which supports them in monitoring all of these aspects is greatly appreciated.

Efficient Heat Detection

One of the most demanding tasks for farmers is to detect the heat which is a critical component in dairy farms. Any improvement in herd reproduction management means one step further towards sound and more profitable farming.

Show more

Hence, the efficient and accurate detection of oestrus and the timing of the subsequent artificial insemination are key factors. A failed heat detection is a major issue contributing to low fertility. The bovine estrus cycle averages 20 days in heifers (heifer is a female cattle that has not yet calved) and 21 days in cows (female cattle which had one or more calving). The oestrus cycle has a range from 18 to 25 days. Therefore, approximately half of the heats remain undetected on traditionally operated dairy farms that search for cows in heat around day 20 or 21. According to recent research based on milk progesterone concentrations, up to 15 percent of the cattle intended for artificial insemination are not in heat. A failed oestrus detection comes in significant economic loss for the farmer.

To demonstrate how important accurate heat detection: the functional vital life of the bovine spermatozoa in the reproductive tract has been estimated at 24 to 30 hours. The transport of viable spermatozoa to the oviducts requires a minimum of 6 hours to obtain a population capable of fertilisation. The average duration of heat is 15 to 18 hours, but heat duration may vary from 8 to 30 hours among cows. This makes the time window for artificial insemination rather short and shows how important a personalised decision support system is for the farmer in these regards.

-8%

Shortening the fertilisation period

-10%

Use of antibiotics

-20%

Labour time of visual animal monitoring

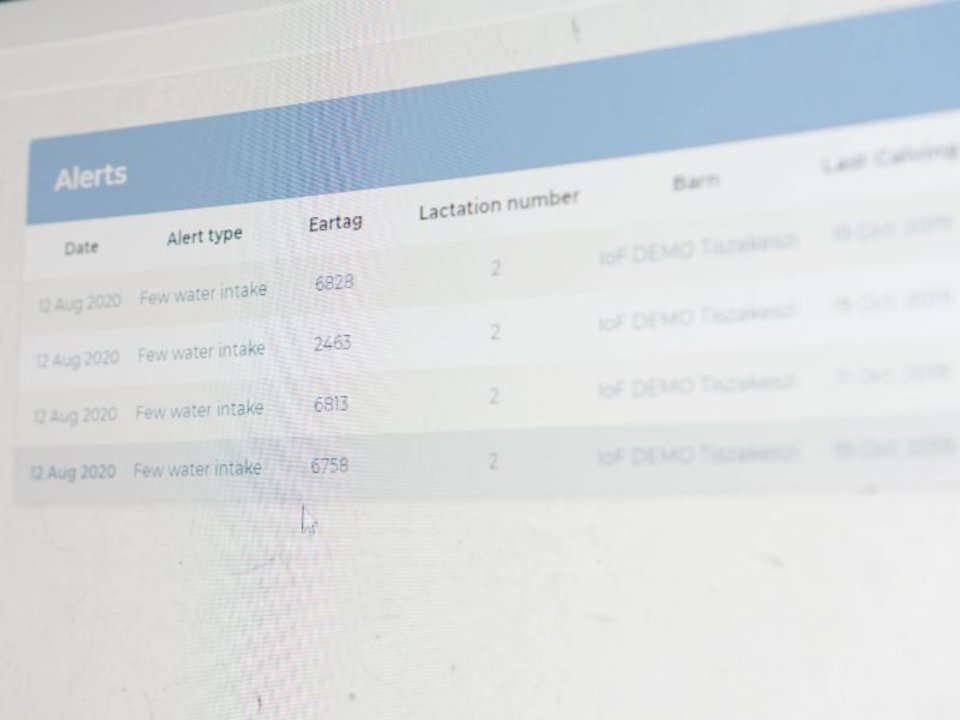

Restlessness and overall physical activity increase significantly during estrus. The Moonsyst Smart Rumen Monitoring Bolus is thus designed to identify behavioural changes before they can be visually detected. All the data gathered by the device which is placed in the reticulum (second chamber in the alimentary canal of a ruminant animal), is centralised and processed in the Mooncloud software/application. Over the time of the project the researchers also helped the end-user to reduce the amount of medication and treatments. The gateway is required to retrieve the information from the boluses. The team came up with a clever solution. The data is stored locally in the rumen bolus and only sent to the gateway once the animal is close enough. The bolus attempts to send the data every 30 minutes and measures in every 10 minutes. The durability of the battery is 6 years.

The average rumen temperature is between 38 and 39 °C. The incoming data are constantly analysed and alerts sent to the end-user dashboard, in case the rumen temperature of an animal exceeds 41,3 °C that refer to illnesses, fever or other diseases. Generally, a high rumen temperature requires urgent action and due to the early detection, treatment can be started before physical symptoms appear. Before we leave Hungary, Peter Gesler tells me that they are currently developing the option of including microphones which could be turned on for a couple of seconds to get even greater insights. These efforts won the use case’s solution: a certification of improving animal welfare by the Szent István University of technology in Hungary. Moreover, the machine learning (artificial intelligence) of the entire system continuously improves its accuracy over time even though the behaviour of dairy cows can vary greatly even within one farm. The boluses can provide useful information both to the nutritional management of the farm and to nutrition companies.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

Accurate heat detection with AI based algorithms

Continuous animal health monitoring

Affordable monitoring system for all herd sizes

Maintenance free operation

Alerts before the physical symptoms are visible