Introduction

IoT is about connecting systems so as to enable an integrated, multidimensional view of farming activities and allowing a deeper understanding of how ecosystems work. This is based on the extensive use of information and communication technologies (ICT) that involve large amounts of data, physical and virtual sensors, control loops, networks, models and optimisation techniques to improve both producer and consumer decisions. The chain-integrated greenhouse production use case aims to develop a decision support system (DSS) for the greenhouse tomato supply chain based on IoT technology. Standardized information will increase interoperability along the production chain, with easier quality and safety management, improved products and processes and a lower environmental impact as the intended result.

Leveraging data sources to optimise production

The largest concentration of greenhouses in the world is in the Spanish province of Almería, where more than 30.000 ha are used for vegetable crop production. With a total production volume of 3 million tons of which 70% are exported, the region contributes 30% of Andalucía’s agricultural value.

Show more

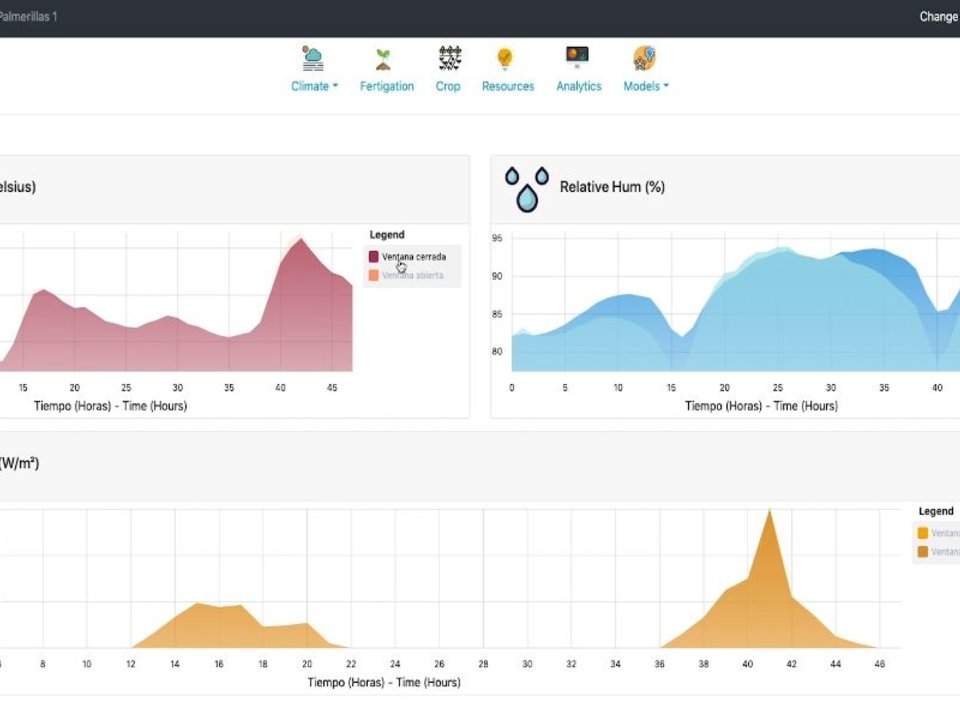

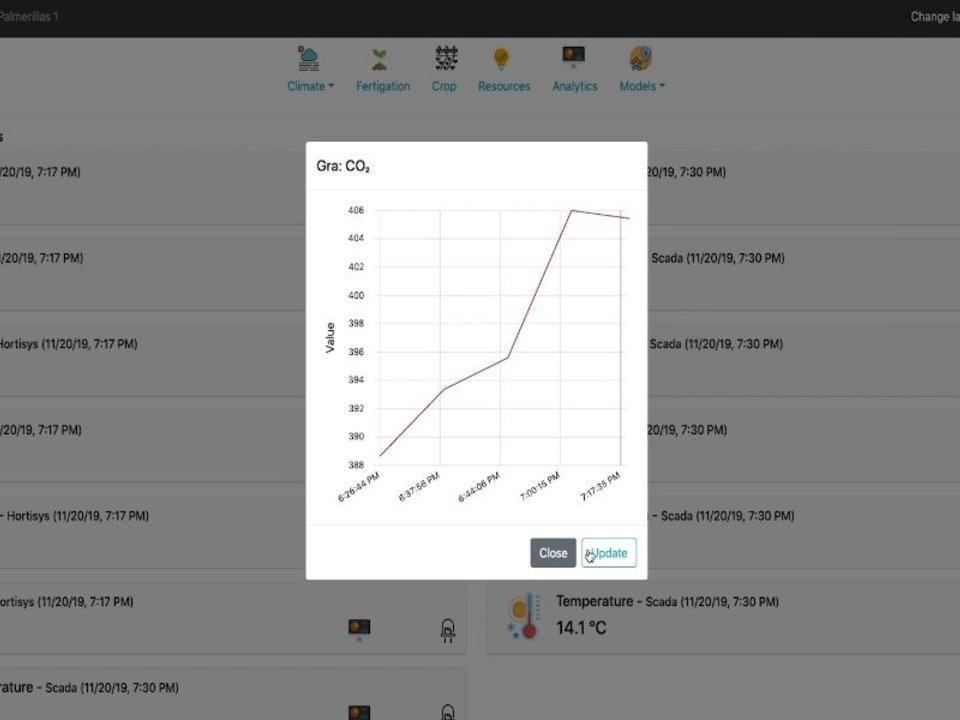

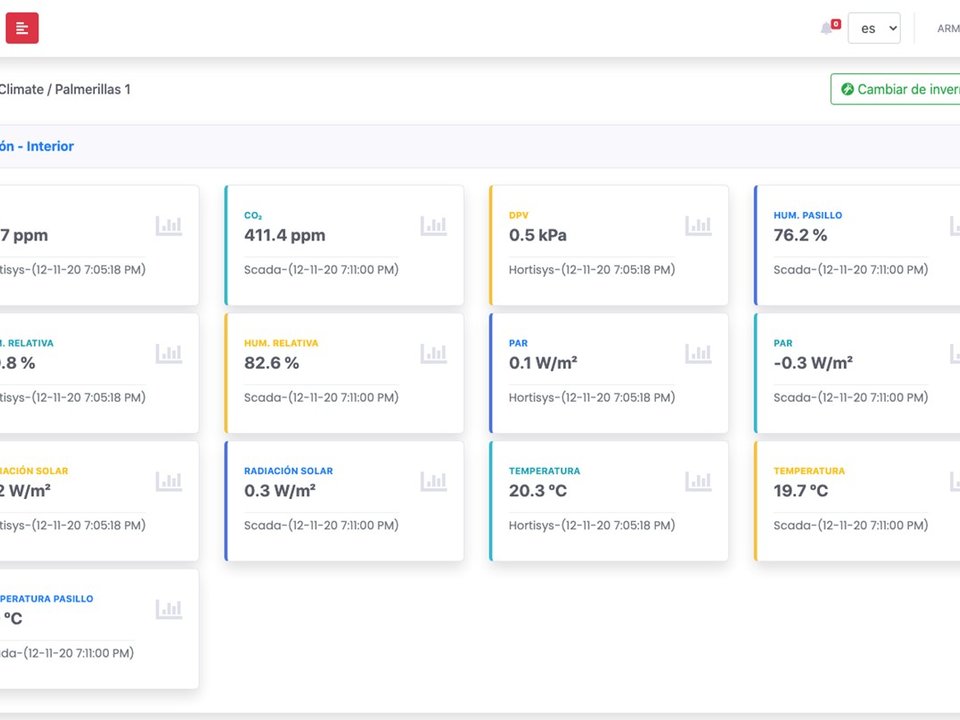

In light of this, the socio-economic importance of Almería´s agricultural production is evident. However, the question of environmental and economic sustainability is ever-present: competition is fierce, demanding improvements in productivity and quality to maintain yield and market value. Technology and innovation are essential tools in seeking solutions to these challenges. By leveraging an Internet of Things (IoT) based data sharing system which combines data from farmers and publicly available data, Jorge Antonio Sánchez Molina, the Use Case Coordinator, and his team optimise the management of greenhouse tomato production in terms of water, fertiliser and energy use efficiency. The so called iVeg application integrates heterogeneous data sources from different time scales such as climate control sensors, weather forecasts, grower decisions as well as agricultural and environmental public authorities. The aggregated output of the use case’s web-based decision support system (DSS) can be shared between farmers, technical engineers, production planners, the handling and transport industry, retailers and customers. This enhances transparency, quality standards, product and process information in every phase of the supply chain and contributes to the standardisation and interoperability of information. Moreover, FIWARE IoT platform integrated a novel service called greenhouse model as a service (GMaaS), running on Matlab Production Server, where greenhouse models are available to estimate indoor climate, crop production, and irrigation values. The inclusion of this new feature has also meant a complete change in the design of the user interface to adapt it to new trends and to make all the information available to the user, clearly and simply. Thus, the GMaaS option provides cloud-based models for all the greenhouses registered in the platform, without any software or device dependence.

+6.9% up to +8.3%

Productivity (kg crop harvested per m² per year)

-5.2%

Crop cultivation costs

-5.3%

Pesticide use

One of the most outstanding new features is the integration of weather forecast according to the positioning of the greenhouse employing latitude and longitude with the meteorological service of WeatherBit. This service does not only inform the end-users about the current weather alongside a 16-day forecast but alerts them about severe weather conditions in their area. The climate and growth models of the greenhouses are subsequently adjusted accordingly. The use case has also integrated a fertigation model which, in combination with climate and growth models, allows the researchers to know the future requirements of the nitrogen and water requirements for the next 48 hours. This helps the end-user to reduce the use (and waste) of precious resources like water, pesticides, fertigation, or energy. Furthermore, it avoids pollution, thereby helping to improve the sustainability of the production process

Identifying the right components

This use case has tested different technologies like weather stations and standards integration. Problems occurred, however, regarding the adaptation of these solutions to the specific conditions of greenhouses.

Show more

Cropping under plastic requires a new type of IoT device which can resist high humidity and temperature or the presence of sulphur condensation which can be found in a greenhouse but not in other cropping system. Most of the solutions have been tested with success in outdoor conditions but not under this intensive production. This leads to system failures and consequently disrupts the end-users trust in the solution. The use case team learned that maintaining the trust of the farmers is key when it comes to digitalising agricultural practices. It is paramount for ICT technology manufacturers to test equipment in the actual conditions the devices are supposed to operate in. To find the perfect components for their application field, the team consulted with our fruits use cases Automated Olive Chain and Fresh Table Grapes Chain. Ultimately, new measurement stations from Hop-Ubiquitous were integrated in the IoT platform.

Cooperative models for food quality

Traceability systems are key to assuring food safety, creating a benefit for food supply chain components. The current proliferation of technologies such as IoT and big data analysis leads to a new generation of more functional, but complex, traceability systems.

Show more

Organisational models based on the cooperation of multiple small and family farming cooperatives, play an important role in high standard agricultural production and the subsequent commercialisation processes. These cooperative models function as both social and economic networks, with significant impact in the rural areas. By using the province of Almeria and its testing sites as an example, this use case studies the traceability systems, considering the different stakeholders and their interrelation. This implies defining clear rules of exchange of the results of the big data analysis and taking privacy rules into account.

+2.7% up to +4.8%

Energy efficiency

-5.3%

Water contamination (kg nitrogen per soil ha)

-4.3% up to -5.6%

Water use

In the case of the handling industry and transport sector, the integration of sensors installed in the trucks in the IoT platform allows the optimisation of storage and handling conditions for the entire tomato supply chain. Thereby addressing societal and environmental concerns in terms of unnecessary food wastage. An improved technological infrastructure prevents significant post-harvest losses occurring in the supply chain. When innovation is cultivated, this use case is rising to meet the demand. Hence, over the course of the project the researchers have detected some parallels between Almería’s model and certain areas in China, mainly in the areas of Beijing-Tianjin-Hebei and Shandong. Another objective of this work is to deepen the understanding of these similarities and analyse the possible application of the findings from Almería to China.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

IoT based data sharing system for the Decision Support System (DSS)

Standardisation and interoperability of information

Increased transparency about food quality and standards (PDOs and organic certifications)

Improved traceability, safety management, quality control and sustainability in the value chain

Enhanced social-economic-environmental sustainability