Introduction

The EU is the largest producer (accounting for almost three quarters) and consumer (accounting for almost two thirds) of olive oil in the world. In 2014, the EU produced 2.482.500 tons of olive oil and 794.000 tons of table olives, while consuming 1.731.000 tons and 530.500 tons respectively. However, increasing competition from other countries and the rapid decline in olive plantations caused by the bacterium Xylella fastidiosa puts the olive sector under pressure. As a response, this use case explores how technologies can help alleviate the pressure and boost resource use efficiency. To validate their solution under different environmental conditions the team of Use Case Coordinator, Rafael Angel Ferrer Martínez, relies on four test farms in Greece alongside seven in Spain. Regardless of the location, the overall focus of the use case lies on a more sustainable way of farming while dealing with climate adaptation. This includes traceability for the entire olive chain, providing information on irrigation for end-users and olive farm advisory boards along with monitoring and controlling the olive oil extractability and quality.

Adopting IoT solutions to different requirements

As you can imagine, having various test farms in two countries with differing conditions did not make things easier for the use case because specific challenges arose in each location. In hindsight, though, it helped the team to design a robust solution, capable of adopting to individual requirements. Since you are probably eager to find out about it, let us dive right into the matter.

Show more

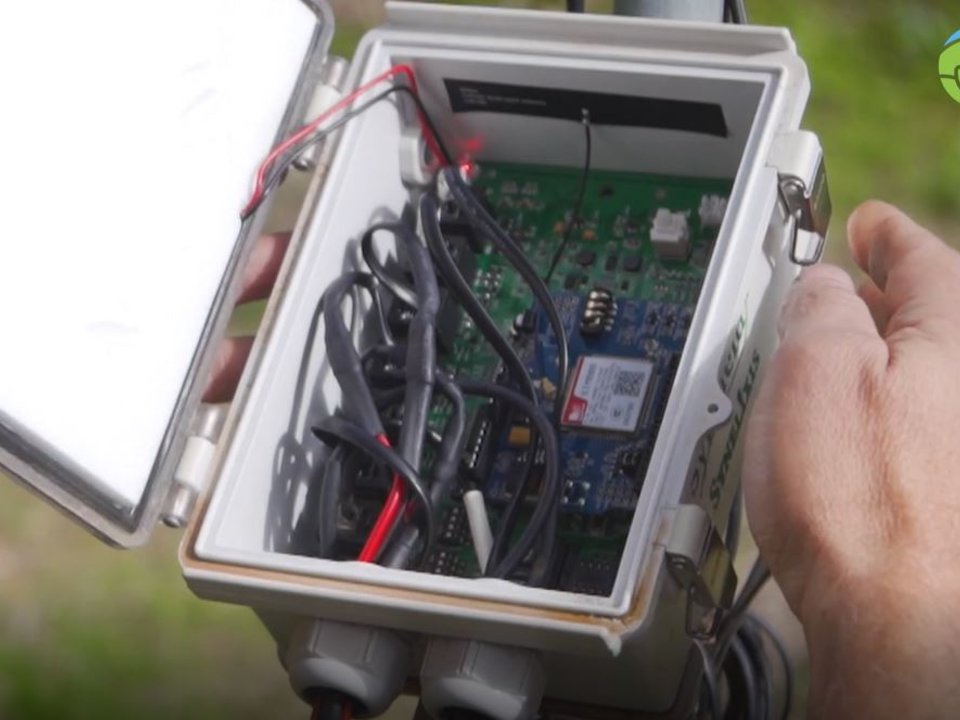

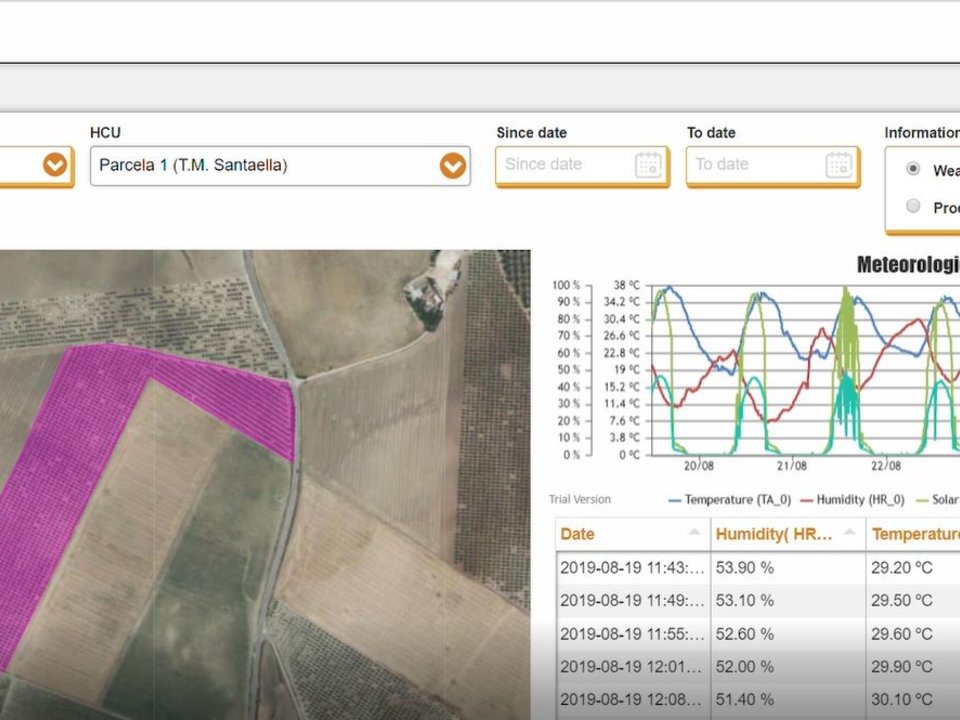

In Spain as well as in Greece, the use case worked with local IoT solution providers – namely, Synelixis in Greece and Hispatec in Spain. These partners have installed complete software solutions centralising weather stations, soil moisture plus temperature sensors, soil electrical conductivity sensors, solenoid valves, irrigation pumps controllers (with on/off switches) in addition to water pressure sensors. This use case is mainly active in places that have sparse or seasonal rainfall which could not sustain agriculture without irrigation. Hence, the team works together with an advisory board with great expertise in irrigation models: TECNOVA for the Spanish test farms and AUA for the Greek ones. In areas that have irregular precipitation, irrigation improves crop growth and quality significantly. By allowing farmers to grow crops on a consistent schedule, irrigation also creates more reliable food supplies. Therefore, it is important to use this precious resource as efficiently as possible. Irrigation decisions based on weather forecast, weather and soil data improves farming practices and leads to those important water savings. This use case is not the only one dedicating their works to the reduction of water consumption in Mediterranean areas. To achieve this common goal, the team collaborates closely with another of our use cases: Fresh Table Grapes Chain. In both use cases the soil moisture conditions are measured, monitored and assessed as a first step. This way, the water requirements of the olive trees, the grapevines or any other crop can be met during each crop stage. Before placing the sensors in the field with olive trees, the team carried out a soil electrical conductivity test to assess the required number and type of sensors needed to strike a balance between expected results and costs for the end-user.

The farm management software this use case relies on is SynField which provides the options of irrigation management, precision fertilisation, pressure network management and prediction of diseases in different crops. It gathers environmental as well as soil conditions in real-time and enables the farmer to control various agricultural equipment such as pumps or electro valves because all IoT devices are embedded in the SynField portal. Since the visual presentation of all key parameters - resulting from the entire gathered data – in the decision support system (DSS) is crucial, the researchers improved the farm management software through farmers’ and end-users’ feedback. As a last step, end-users were trained to reap all the benefits this solution has to offer.

+10%

Yield increase (kg/ha)

-10%

Work time (hours/kg)

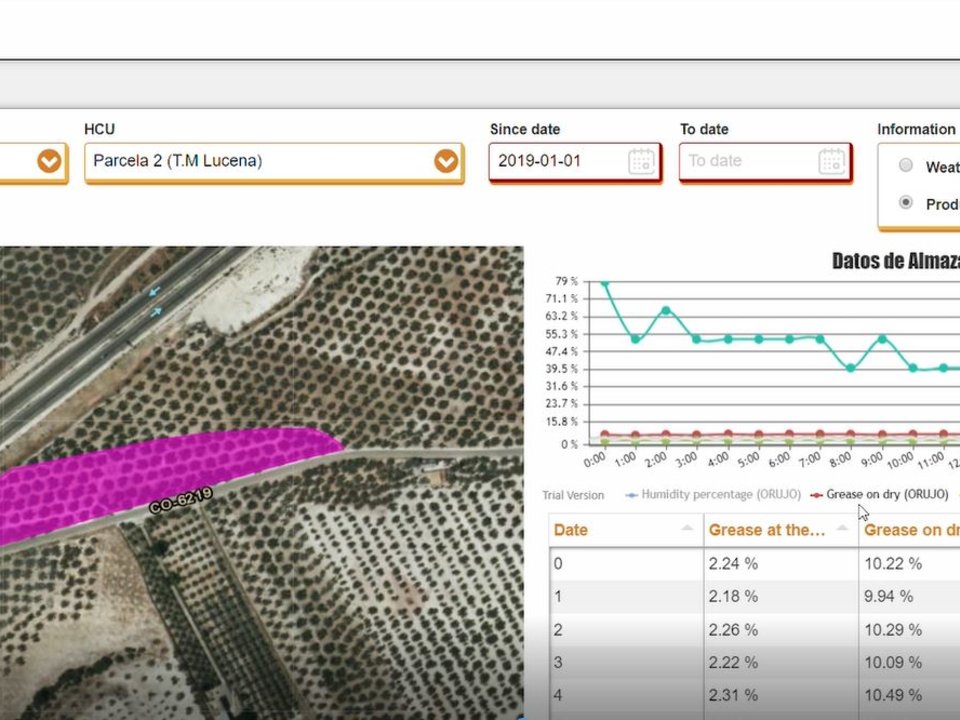

Moving further along the supply chain, this use case also improves the post-harvest aspect of olive production. To validate the key performance indicators (KPIs), they collaborate closely with test farms and olive mills of local producers which are part of the producer groups NILEAS in Greece and DCOOP in Spain. Through NIR (near-infrared) sensors, installed in olive mills, the quality and amount of the oil can be enhanced. This extractability and quality measurement is carried out in real-time as it measures the fat content of the olive oil. Additionally, it informs an enterprise resource planning (ERP) solution to trace back the fields and crops. Since all of this is coming together in one centralised IoT platform, it improves practices on the farm as well as in the olive mills, optimises costs and enhances traceability of the product. Ultimately, helping to quench the Europeans desire for olives and olive oil.

Factors influencing a successful deployment

We previously elaborated the importance of irrigation for agriculture in Mediterranean regions. For IoT devices, however, irrigation or particularly the moisture occurring thereof poses a risk too.

Show more

After extended usage in harsh conditions such as open field agriculture, the team detected problems resulting from condensation. This was due to the air-tight cover in combination with the elevated temperatures inside the devices. In some cases, the internal temperature could reach up to 10°C more than the outside temperature which even had negative effects on the battery life. The problem was solved by utilising ventilation plugs alongside heat insulation material beneath the solar panel of the device. Ventilation plugs are designed for venting air while preventing water intake. A device cover that sufficiently protects the sensors is also important in terms of external damage. Reasons for dysfunctional IoT devices can be rodents biting through cables, the battery life of probes or sensors and damage caused by agricultural machinery or labour execution. Unfortunately, sometimes the dysfunctionality is rather related to vandalism than to technological failure per se. Since the entire solution depends on data gathered from those devices to calculate the key parameters for the end-users, it was paramount to ensure a suitable protection for the hardware.

-15%

Production costs

-15%

Energy consumption

Something that is overlooked all too easily when installing an IoT solution on a farm is the correct placement of IoT devices. This is especially important for soil moisture sensors. If only one soil moisture sensor is installed per field, it must be placed in the dominant soil type of the field. Additionally, the correct placement can minimise sensor cabling and interconnection, which is a common cause of failure. In case the IoT device is self-powered using a solar panel as is the case for weather stations, device placement should take into account that the panel will not be completely shaded in the future (i.e. due to crop canopy growth) and that birds would not sit on it and litter the panel. Lastly, problems with dataloggers’ stability were addressed by improving battery life.

Sustainability results and future potential

The technologies leveraged by this use case provide many examples of how IoT technology can also contribute to sustainability. With the improved water and resource management, sustainability is even directly realised.

Show more

Especially because many of the olive farms can be found in Southern Europe, efficient water use is very important in areas with low precipitation. While this is the common denominator of the test farms in Spain and Greece, the average farm size or number of fields is not. The olive tree fields are most of the time situated either on large acres or many smaller fields. Spanish farmers tend to the prior. Greek farmers on the other hand usually own several smaller fields. In addition to that, their fields might not always be close to one another. As a response, the use case offers the remote monitoring, remote controlling and scheduled water irrigation, enabling the farmers to make decisions from a distance. Thanks to the applied innovations this also increases the yield and profitability, while the fuel and electricity consumption simultaneously decrease. This further mitigates the emission of air pollutants such as CO2 and NOx. Reducing the resource consumption mainly in irrigation activities, will not only optimise energy and fertilizer consumption, but contribute significantly to biodiversity as more living organisms can survive in their natural habitat. At the same time, it reduces crop diseases in the field and thus potential pre-harvest losses deriving from improper water management.

-15%

Water consumption

-10%

Fertiliser use

With several smaller fields scattered over regions comes another challenge. It can make the purchase of IoT technologies costly and an efficient as well as sustainable installation difficult. Sharing of weather data can eliminate the need to install weather stations in each field, which consequently cuts costs in investment and significantly increases the return of investment (ROI). A solution could also be to share IoT technologies with neighbouring farmers. We would thus like to encourage data providers as well as farmers to collaborate with each other when it comes to adopting IoT technologies in agriculture. It can, as this use case prove, make a significant difference in efficiency, sustainability, climate control and profitability: more output, with less input.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

Optimisation of water and energy consumption in irrigation through more accurate recommendations based on IoT solutions

Information about agronomic practices with higher accuracy due to communication of IoT solutions with machinery

Efficient management of oil extractability and quality thanks to NIR sensors in olive mills

Traceability along the whole olive oil value chain