Introduction

When we arrived in the Nouvelle-Aquitaine region with Bordeaux as its capital, Mario Diaz Nava, the Use Case Coordinator, invited us on a trip to the heart of European viticulture. With over 2000 estates averaging at 35ha each, this region is unequivocally considered the epicenter of wine. One of them - the estate Denis Debourdieu - is part of this use case and dedicates their 135ha to the optimisation of the entire viticulture value chain. It is run by Jean Jacques, along with his brother Fabrice, who are following in their grandfather’s and father’s enthusiastic footsteps to improve viticulture in this region. While his grandfather at the time initiated a step from mere quantity to quality as he identified the molecules responsible for the taste of wine, Jean Jacques now leverages IoT technology to control every aspect of the production process, putting the Dubourdieu family Domaines once again at the forefront of innovating wine production. As viticulture is deeply rooted in historical guidelines with delicate or even tiresome practices, the team strikes an equilibrium between respect to traditions and in-field sensors embedded in weather stations or cameras combined with algorithms. For instance, the irrigation of vines classified as AOC (controlled designation of origin) in France is prohibited during a certain period to limit an excessive burden. It is only exceptionally authorized due to extreme ecological conditions. So, how can one monitor all those parameters that are crucial when producing wine of finest quality? And it goes without saying that implementing such a system as the first necessitates to overcome challenges, deal with frustrations but first and foremost thrive on the successes.

Establishing an efficient LoRa Network

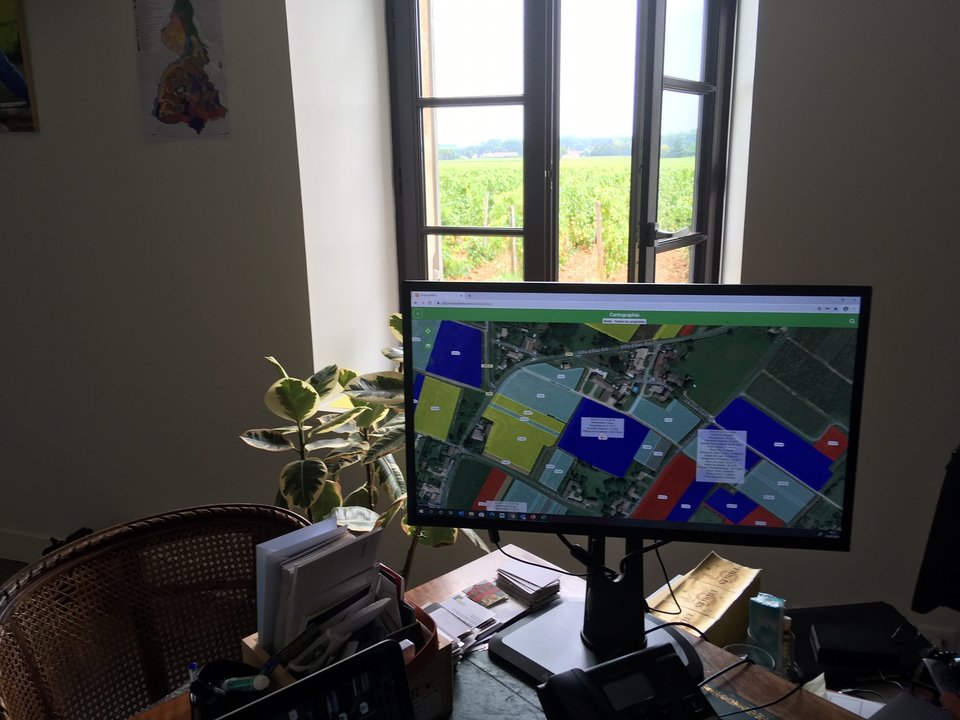

The Denis Debourdieu estate is spread out over the different areas Sauternes, Barsac, Graves and Cadillac Côtes de Bordeaux, each with their own specificities and distinct wines. To make sure all sensor nodes installed successfully communicate with the gateways, the team relies on a LoRa (Low-power long range) network.

Show more

And we are talking about a plethora of 74 devices: 8 mini-weather stations, 9 Davis weather stations, 28 water meters, 7 electricity meters, 1 fixed and 1 mobile camera sensor and 1 insect trap sensor in the field. Moreover, 9 mini-weather stations are deployed in the cellars and connected to the power supply and 10 more connected wirelessly. The goal is to cover as much area with as little gateways and relays as possible to avoid an unnecessarily complicated LoRa network. To reach every gateway, for instance, some sensor nodes needed a bigger antenna with a higher gain to connect to the network.

The team further developed, deployed and validated a network server (LoRa server) in order to have a complete, independent, reliable and secure solution. The LoRa server supports the MQTT (Message Queuing Telemetry Transport) protocol which retrieves the data and makes them interoperable through the FIWARE software ecosystem. The software is not only in charge of activating the sensor nodes, it also decrypts different standards and sends the gathered information to the centralised application server. As a last step, Mario Diaz Nava and his team set up a maintenance contract and data sharing agreement with the farmer or end-user to ensure all involved parties get the most out of the provided service.

12 000€

Implementation costs

While there are sensors with batteries that recharge through water flow, for instance, this does not yet exist for other sensor nodes. To address this challenge, the team took several measures to optimise the power consumption in order to guarantee long-lasting autonomy for all battery-powered sensor nodes. Firstly, a sleep mode has been introduced to lower the consumption during the minutes the devices do not transmit any information. Secondly, in addition to solar panels, certain weather stations were equipped with a higher battery capacity to ensure their full autonomy to receive real time meteorological data from the location at any time. Lastly, the sampling rate was changed from 15 to 20 minutes. The weather stations measure all common parameters such as wind, precipitation or humidity but one of them is of utmost importance when growing wine in this area: temperature. During cold springs, frost is the biggest threat to viticulture and can wreak havoc in the fields, causing significant harvest losses. Therefore, the temperature must be constantly monitored during those months.

Traditions in line with smart farming practices

We talked about tiresome, traditional practices in the introduction. One of them was counting the number of healthy vine stems in the field to roughly estimate the harvest.

Show more

his was done by hand and if you imagine a field with several hundreds or even thousands of vine stems, one thing was clear: the team had to come up with a more efficient solution. Now this task is carried out through a tractor-mounted camera system which is able to take an image of every plant at high speed. To simplify the work of the winegrowers, the camera is fully automated while the system is guided by an on-board GPS.

To overcome the problem of processing images taken in different lighting conditions, the use case came up with a clever idea. What it needed was an understanding of an old cinematic method called “day for night”. This technique is used to simulate a night scene while filming in daylight. For the team that meant they needed a strong external light source in form of a xenon flash which is perfectly in sync with the automated camera. After several years of research and improvement, today the system not only helps to accurately estimate the yield of the harvest but also monitors the health of the plants.

-15% (120€/ha)

Pesticide costs

-15% (13€/ha)

Fertiliser costs

-5%

Treatment frequency

In addition to the mobile camera attached to the tractor, the researchers installed a static multispectral camera at strategic spots to monitor the phenological stage of the vine. To keep the price of the multispectral camera low, they came up with another original solution. A lighting system consisting of LEDs with different wavelengths can provide accurate multispectral information about the plant. The acquired images are used to determine the development phase of the vine, but also the photosynthetic activity from the infrared images. Next to the static camera is an insect trap equipped with a solar panel and a simple camera which takes one picture every day. It helps to identify the various insects over time with the aim to avoid unnecessary phytosanitary treatments with pesticides, simply by predicting which conditions are most likely to correlate with certain insects. To end up at conclusions like these, the use case merges and subsequently extrapolates the data of the static camera - without any spatial change but temporal change – and the information gathered by the tractor-mounted camera – with spatial change but no temporal change as the counting of the vine stems is done within a few days. As a next step, they are currently exploring machine learning techniques for early disease detection which up until now had to be done by the farmer through visual inspection. This is especially important for so called quarantine diseases which cannot be cured and necessitate the destruction of the affected plants.

Challenges during implementation of sensor nodes

One recurring problem this use case faces is the continuous destruction of their mini-weather stations deployed in the field. The obvious solution would be to simply make the weather stations smaller, but this is easier said than done.

Show more

The data derived from them is crucial for early decision-making to prevent fungi from even occurring. Therefore, it must be as accurate as possible and a precise weather station needs measuring instruments of a certain size. That left the team stuck between a rock and a hard place. The first attempt leveraged the GPS on the tractor to inform the drivers when they were getting close to the coordinates of a sensor node in the middle of the vineyard. Unfortunately, that was not accurate enough to prevent the destruction of sensors. In the end, they solved it in a simple but very practical way: signs at the exact location of any device. This is not only useful for the drivers to avoid any damage but also helpful in terms of maintenance as the search for the needle in the haystack or rather the sensor in the field becomes obsolete.

-10%

Water consumption

-10%

Energy consumption

To address resource use efficiency, the researchers installed water meters at every irrigation source to closely monitor the use of this precious natural resource and immediately detect eventual leaks or damages. In a similar vein, they mounted electricity meters in all cellars and wine production areas to measure, control and subsequently optimise the resource consumption. At the end of the day, the deployment of a smoothly functioning IoT system is not easy and requires different types of expertise such as ICT, plumbing, electricity alongside cross-sectoral knowledge and a lack of either of these has a significant influence on the timeline as well as success of the implementation.

Post-harvest storage of wine

The harvesting of wine grapes is one of the most crucial aspects in the process of winemaking. The time of harvest is determined primarily by the ripeness of the grapes as measured by sugar, acidity and tannins.

Show more

In addition to that, winemakers base their decision on the style of wine they wish to produce. Unsurprisingly, the weather also influences the harvesting time since extreme heat, rain or humidity can bring about various vine diseases while hail or frost significantly damage the grapes.

Once the vine has been harvested, processed, appropriately aged and bottled, it is stored in cellars. During storage, the temperature and humidity in the cellar are extremely important factors, influencing the quality of the wine. Those parameters are thus closely monitored and adjusted through an air conditioning system. If the sensors record any inconsistencies at this stage, alerts are immediately sent to the management system Process2wine. The application gathers all data from each mini-weather station and sensor node and presents it effortlessly to the end-users so they can leverage the information. This helps the winemaker to initiate countermeasures and stabilise the conditions before the wine quality is negatively impacted. Ultimately, it enables the end-user to monitor every step along the value chain and helps them comply with ISO (the International Organization for Standardization) wine making guidelines which regulate the application of pesticides, for instance, which is only allowed below windspeeds of 19 km/h. The winemaker can even retrieve information on the ecological footprint of each bottle. All of this, simply by opening the application on the smartphone. Thereby, the use case has pioneered in deploying an infrastructure which simplifies the complexity to manage wine growing and production, increases the wine quality and reduces the resource usage. Moreover, it is foreseen to install new devices such as sensors and actuators, allowing the development of new applications to monitor and control all the processes carried out in the vineyards and cellars. These extensions will be seamlessly possible because the team relied on an open architecture based on LoRaWAN (Long Range Wide-area network) from the very beginning.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

Data gathering in real time from the vineyard (Weather conditions, vine phenological stage) and the wineries (Temperature, humidity, water and electricity consumption)

Data analysis and subsequent decision-making at anytime and anywhere through specialised wine production applications running on mobile devices